The Workstation T-Base V3 expands your FLEXX, turning it into a

compact, open welding station with a digitally-controlled three-

axis work table and a separate height-adjustable laser head.

With a unique control concept, you can extend manual welding

via a precise motion control with sophisticated automatic and

program functions.

Your beneft: increased productivity and replicable welding quality!

| Technical Data | LWI V Nd:YAG 120 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 120 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 160-500V |

| pulse width | 1-20 ms |

| pulse frequency | 1-20 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, water/air heat-exchanger, temperature controlled fan |

| cooling option | external cooler optional, integrated bypass-controller |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions |

| Technical Data | LWI V Nd:YAG 150 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 150 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 160-500V |

| pulse width | 1-20 ms |

| pulse frequency | 1-20 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, water/air heat-exchanger, temperature controlled fan |

| cooling option | external cooler optional, integrated bypass-controller |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions |

| Technical Data | LWI V Nd:YAG 200 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 200 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 200-500V |

| pulse width | 1-30 ms |

| pulse frequency | 1-30 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, water/water heat-exchanger, external cooling required |

| cooling option | external cooling required |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 4 kW |

| dimensions |

| Technical Data | LWI V Nd:YAG 300 W |

|---|---|

| laser safety class | 4 |

| beam source | Nd:YAG, flashlamp, pulsed |

| wavelength | 1064 nm |

| max. pulse energy | 70 joule |

| max. peak power | 17 kW |

| max. average power | 300 W |

| energy adjustment mode | voltage or PWM mode |

| voltage | 200-700V |

| pulse width | 1-30 ms |

| pulse frequency | 1-30 hz |

| pulse fill | 10 - 100 % |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 200 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, water/water heat-exchanger, external cooling required |

| cooling option | external cooling required |

| electrical supply | 3 phases, 400V /50 hz |

| power consumption | 9 kW |

| dimensions |

| Technical Data | LWI V FSS 150 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 15 Joule |

| max. peak power | 1,5 kW |

| max. average power | 150 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1-phasig, 90-250V, 50/60 hz |

| power consumption | 800 W |

| dimensions |

| Technical Data | LWI V FSS 300 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 30 Joule |

| max. peak power | 3 kW |

| max. average power | 300 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | 1 - 100 % |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 1,2 kW |

| dimensions |

| Technical Data | LWI V FSS 450 W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 45 Joule |

| max. peak power | 4,5 kW |

| max. average power | 450 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | - |

| PWM mode | - |

| focal length | 190 mm |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | - |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 2,5 kW |

| dimensions |

| Technical Data | LWI V FSS 600W |

|---|---|

| laser safety class | 4 |

| beam source | FSS FullSolidState Fibrelaser, Diodes |

| wavelength | 1070 nm |

| max. pulse energy | 60 Joule |

| max. peak power | 6 kW |

| max. average power | 600 W |

| energy adjustment mode | current |

| voltage | 10 - 100 % |

| pulse width | 0,1 - 50 ms /cw |

| pulse frequency | 1-100 hz |

| pulse fill | |

| PWM mode | |

| focal length | 190 mm (120 mm, 300 mm) |

| beam diameter | 100 µm - 2mm, motorized beam-expander |

| microscope | Leica binocular, oculars magnification 20x |

| illumination of workplace | dual LED cold-light, switchable |

| parameter settings memory | 50 settings, individual named |

| energy measurement system | integrated |

| controller | multi-controller-system, self-diagnostic-system, plaintext for maintenance and status messages |

| interface | RS232, CAN-Bus |

| shielding gas supply | flexible nozzle, adjustable gas delay |

| cooling system | integrated, closed, temperature controlled fan |

| cooling option | |

| electrical supply | 1 Phase , 90-250V, 50/60 hz |

| power consumption | 2,5 kW |

| dimensions |

Which laser beam source is right for you and your application? Learn about the differences, advantages, and disadvantages here.

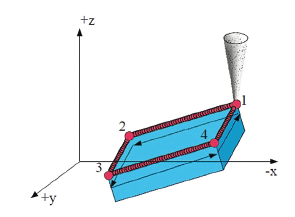

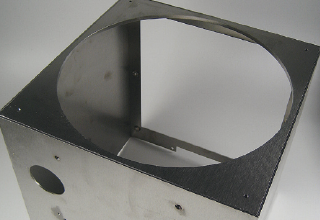

The XY cross table, with its stable precision linear slide, screw drive and high-resolution stepper motor, provides the basis for exact positioning and high repeat accuracy. Your work piece can be accurately and flexibly set on the plainmilled aluminium slot profile slab.

Thanks to its elaborate linear slide on four large stainless steel shafts and precision cylinder sleeve, the precise steering of high loads is guaranteed. The high-resolution screw drive with its powerful stepper motor provides both exact positioning and high processing speeds.

Precisely controls axis movements. This extends manual welding by its sophisticated automatic and programable functions. Touchscreen and Joystick terminals directly in your workspace provide a unique, simple control concept. Thanks to the completely integrated hardware, a separate computer is not needed.

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

You can process circular type contours by using the PCD function with the XY axis. The circular path is precisely defined through the teaching of only three support points. You do not need to know the center or the diameter; the position on the work piece is optional. You can move along the programmed course either forward or backward by using the joystick.

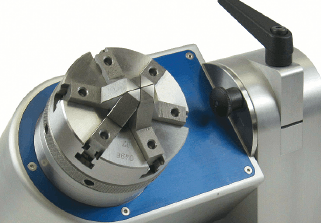

Specially developed turning units increase the user value of your workstation. They incorporate all functions of CAN-Step control, available at the touch of a button, including pulse synchronization and „Teach in“ programming. Additional features: • Swivel-mounted • Free implementation up to Ø40 mm • different chuck types, chucking range up to Ø 160 mm.