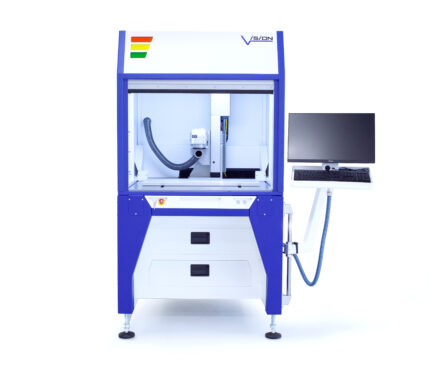

The compact HAWK 2 laser processing station offers maximum flexibility and performance.

The use of the latest laser technology with the best beam quality guarantees stable work with the highest quality standards, even under production conditions.

Depending on the task, the laser device is equipped with a fiber laser, diode-pumped solid-state laser or CO2 laser.

The HAWK laser station can be optimally adapted to any requirement thanks to the use of technical aids such as a multi-axis system, parts apparatus, camera recognition, rotary table or film handling. There is a large laser protection window in the electrically controlled lifting door, which allows you to observe and control the marking process throughout the entire process.

Areas of application

Laser marking:

– Laser marking and laser engraving of flat surfaces and rotational surfaces

– 3D laser marking and laser engraving

– Hallmarking

– Logo marking

– Barcode, data matrix code

– Serial numbers

– 3D micro-engraving

Laser drilling:

– Single-pulse drilling

– Trepanning drilling

– Helix drilling

Laser cleaning:

– Degreasing of surfaces

– Activation of bonding surfaces

Laser cutting:

– Remote laser cutting

– Laser fine cutting

Laser micromachining:

– Laser microstructuring of flat surfaces and rotational surfaces

– 3D laser microstructuring of free-form surfaces

Laser welding:

– Remote welding

– Laser microwelding of flat workpieces and rotary parts

Special version with drawer for large and heavy workpieces

| Technical Data | IPG Fiber 20W |

|---|---|

| laser head | diode-pumped Ytterbium Fiberlaser, with integrated pilot-beam (red) |

| cw-Betrieb | no |

| Wellenlänge | 1064 nm |

| Leistung | 20W |

| M2-Richtwert | 1,5 |

| Q-switch-Betrieb | |

| Pulsenergie | 1 mJ at 20 kHz |

| Peak to Peak Stabilität | 5% |

| Pulsdauer | 100 ns |

| max. Pulsfrequenz | 80 kHz |

| Abmessung Lasermodul in mm | 215 x 95 x 286 mm |

| Umgebungstemperatur | 0°...35° |

| Dimensions | --- |

| Technical Data | IPG Fiber 30 W |

|---|---|

| laser head | diode-pumped Ytterbium Fiberlaser, with integrated pilot-beam (red) |

| cw-Betrieb | no |

| Wellenlänge | 1064 nm |

| Leistung | 30 W |

| M2-Richtwert | 1,5 |

| Q-switch-Betrieb | |

| Pulsenergie | 1mJ at 30 kHz |

| Peak to Peak Stabilität | 5% |

| Pulsdauer | 100 ns |

| max. Pulsfrequenz | 80 kHz |

| Abmessung Lasermodul in mm | 201 x 95 x 286 |

| Umgebungstemperatur | 0...35°C |

| Dimensions | --- |

The clear and permanently legible identification of medical products is no longer a competitive advantage today — it is a regulatory necessity. Our new ultrashort-pulse laser marking system was developed precisely to meet these requirements and sets new standards in irreversible laser marking for medical instruments, surgical equipment, implants, and complex medical components.

In annealing marking, the material is subjected to high heat input (high pulse overlap, low pulse peak power) to create annealing colors (blue to black). This process does not affect the surface of the material. Temper coloring is only possible with stainless steels, depending on the carbon content. more information

In addition to metal or plastic, the laser can also be used to mark other materials such as ceramic and wood.

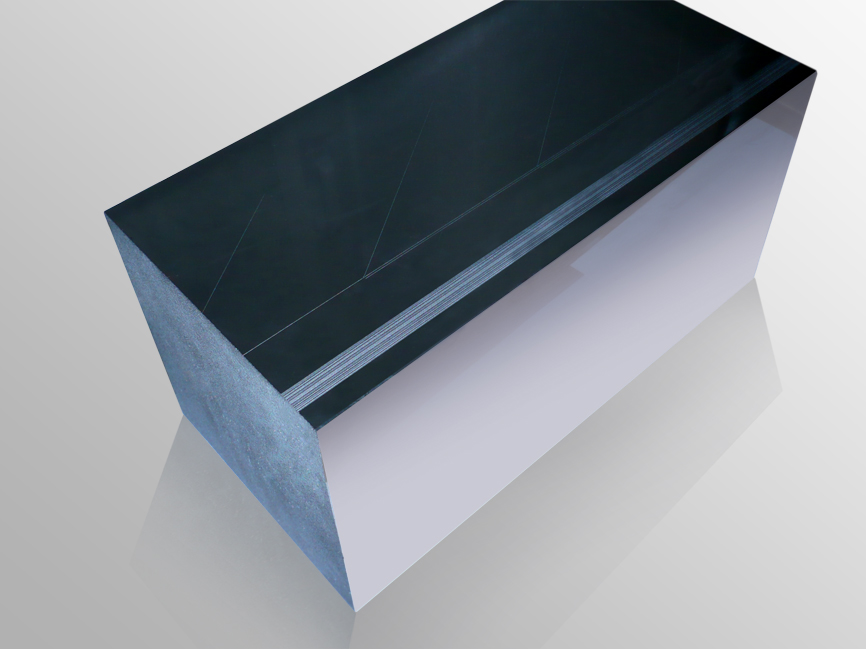

In engraving, contrast is created by removing material. The material is vaporized and partially melted by short, high-energy pulses. With deep engraving, 2½ -dimensional structures are created in this way, as with stamp engraving, for example.

An innovative marking process and special image recognition methods enable the wafer producer to trace the individual wafer back to the respective silicon pillar throughout the entire production process. The pillar is marked with a barcode that contains production information such as production date, pillar number, etc. In addition, the position of the individual wafer in the column can be traced using a special code.