For Laser marking we have to separate by two complete different kind of lasers:

a) CO2 Laser mostly used for organic materials and many kinds of plastics

b) Short pulsed IR Lasers used for all kinds of metals and also for a lot of applications in plastic marking

We will now go deeper into the short pulsed IR lasers because these are the standard catalog marking systems of Vision.

For special projects we can also quote CO2 systems but 90% of our sales are short pulsed IR Lasers.

In the past this was mostly lamp pumped YAG Lasers. Huge machines with external water chillers. Such systems still are sold from China today.

In the early 21th century diode pumped YAG systems came up.

Dimensions go down strongly and also most units did not need a chiller. Except of very special cases all this is history.

Today the market is dominated by fiber lasers and this for a very good reason!

Fiber Lasers are really small and available as standard units up to 100 W. In very special cases there is short pulsed lasers with power up to 1000 W available.

The mostly used power is the 20 W Fiber laser. Today this 20 W fiber lasers are made in many 1000 Systems per year. In the past, laser marking was something very special but today every machine shop should have a system.

In the time of digitalization, most companies want to collect data wherever possible and require information of production as batch number , date of Manufacturing and maybe their Logo.

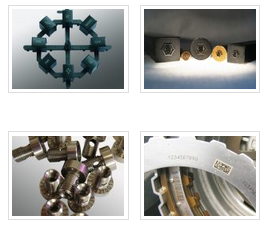

Vision “OEM-Module” or special plants constructions

There are industrial areas (automotive, aviation and also medical) where parts need to get a huge amount of information. It’s so much information that the surface often would not give enough space to mark all. For this all the information is compressed and hidden into a DMC (Data Matrix Code). Today this is the way how big industries ensure to get all information on each part they use. For this reason by quantity we sold most Laser Marking machines as OEM modules to the German Car manufacturer. But also there a change is coming up and the big companies for example of gear boxes who in the past was marking the parts before assembling, today require from their suppliers the DMC to be already on the part.

In the next Video, you can see marking and verifying the Code. I know that this might be not your business but you could deliver the OEM Module to companies that are building such production lines.

Vision DesktopMark

The cheapest version of our laser marking systems is the Desktop Mark . Even if it is called Desktop Mark, it is not so small. Many really cheap laser marking machines have a very small laser safety housing. Such lasers are mostly used for jewelry applications.

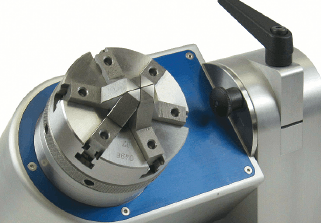

If you want to use the system in manufacturing applications, you will need a bigger space. In many cases you might need a rotation stage that will turn the part during the marking. Such devices need space and so we decide to make the Desktop Mark not really small.

The area you can mark is normally 100 x 100 mm. If you use a special Objective, you can mark 160 x 160 mm. The system has a motorized and digital Z axis so that you can adjust the focal plane easy and even put the position to memory.

An option, as mentioned above, you can add a 4th axis to drive a rotation stage and mark 360° around the parts. (Rotation stage we also have as stock items).

The Hawk is the system that can do all the jobs that might come up in industry . We can offer this systems with all technologies that are available in the market today .

The system comes with digital Z Axis and automatic Front Door as standard . The next higher version might be equipped with additional XY Axis . The Table is made to carry even high load workpieces . The Z axis is with long travel range so that even Objectives with 440 mm can be used without a problem.

4 th axis for rotation stage is also available as option .

For very heavy loads that might be loaded by crane, we can offer a version with drawer that makes it easy to load the machine and bring easily the workpiece into the chamber.

Options for image recognition or measurement are also available as well as 3 D marking with high speed focus shifter. For Laser power you can choose between 20 to 200 Watt as stamdart ot MOPA Version.

In case that the workpiece might be too big or too heavy to load it into a marking system, we developed the Flexx Mark system. This system is easy to disassemble into 3 parts and to store even in smaller cars.

Within three minutes its put together and ready to use. The head is handheld and you can place it onto the workpiece for marking the surface . The software is same as in the big systems so that you can mark from Text to any graphics, DMC or line codes.

The system can be delivered with different shielding adapters to ensure laser safety . Laser safety is ensured by measurement of the Vacuum from dust collector. The available Power is from 20 to 50 Watt in this system.